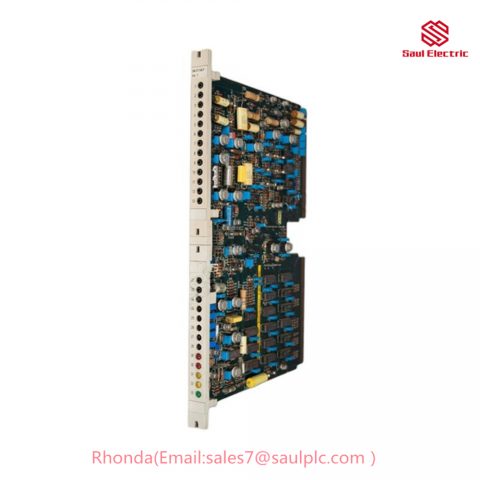

Technical Specifications

Processor Speed:Up to 20 MHz

Memory Capacity:8 KB RAM, 4 KB EEPROM

Communication Interfaces:RS-232, RS-485, DeviceNet

Power Consumption:Less than 1 W

Operating Temperature Range:-20°C to +60°C

Dimensions:100 mm x 50 mm x 25 mm

The ABB DSQC325 Main Computer Board is designed for high-performance applications in the manufacturing industry, featuring an ultra-fast processor that ensures swift response times and efficient data processing.

With its versatile communication interfaces, including RS-232, RS-485, and DeviceNet, the board facilitates seamless integration with various components in your automation system, enhancing connectivity and flexibility.

Equipped with ample memory (8 KB RAM and 4 KB EEPROM), the DSQC325 allows for efficient storage of program code and user-defined data, ensuring robust and reliable operation under demanding conditions.

Featuring a low power consumption of less than 1 watt, this board optimizes energy efficiency without compromising on performance, making it ideal for long-term, resource-sensitive operations.

Adaptable to a wide range of environmental conditions (-20°C to +60°C), the ABB DSQC325 Main Computer Board is built to withstand harsh industrial environments, ensuring dependable performance in any setting.

***************************************************

Annual hot selling advantage products:

ABB PM665、ABB S-073N、ABB S-123H 3BHB030479R0512

Only inventory left, in high demand source

First hand source, affordable price. Spot inventory!

•Shipping Port: Xiamen

•Ship to you via Fedex/DHL/TNT/UPS/EMS

•Package: Original packing with cartons

🗣️ABB Hot Selling Inventory:

3BHE023784 5SHY3545L0014 UFC911B106 3BHE037864R0106 5SHY6545L0001 AC10272001R0101 5SHY6545L0001 5SXE10-0181 UFC921A101 3BHE024855R0101 UFC789 3BHE014022P102 5SHY4045L0006 3BHB030310R0001 5SHY4045L0004 3BHB021400R0002 XVC770BE101 3BHE021083R0101 KUC755AE105 3BHB005243R0105 5SHY4045L0004 3BHB021400R0002 5SHY4045L0004 3BHE039203R0101 S-073N 3BHB009884R0021 ACS6000 3BHB011219R0001 5SHY4045L0003 3BHE019719R0101 5SHY4045L0003 3BHB021400

FAQ

Q: Do you provide a warranty for the goods?

A: Yes, we provide a warranty for all the goods from us.

Q: Could you provide technical support?

A: We’re in this field for more than 12 years. If there’s any problem, please contact us, and we’ll provide suggestions from our engineer to help you solve the problem.

Q: Do you keep goods in stock or only trade?

A: We have a large warehouse for goods. We keep lots of items in stock, so we can promise fast delivery.

Q: Are your goods new and original?

A: Yes, they are new and original.

What is a DCS?

A Distributed Control System (DCS) is a sophisticated, computer-based control system designed to automate, monitor, and manage complex industrial processes. It is widely used in large-scale industrial facilities such as refineries, power plants, chemical plants, and paper mills, where precision, reliability, and scalability are critical.

How Does a DCS Work?

A DCS is composed of several interconnected components that work seamlessly to ensure efficient process control. Here’s a breakdown of its key elements:

- Controllers:

These are the “brains” of the system. Controllers receive data from sensors, process it using pre-programmed logic, and send output signals to actuators to maintain optimal process conditions. - Sensors:

Sensors act as the “eyes and ears” of the system, measuring critical physical parameters such as temperature, pressure, flow rate, and level. This real-time data is essential for accurate control. - Actuators:

Actuators are the “muscles” of the system. They execute physical actions based on controller commands, such as opening/closing valves, starting/stopping motors, or adjusting dampers. - Operator Stations:

These serve as the human-machine interface (HMI), allowing operators to monitor the process, adjust setpoints, and troubleshoot issues. Modern DCS systems often feature intuitive graphical interfaces for ease of use. - Communication Network:

The backbone of the DCS, this network connects all components, enabling seamless data exchange and coordination. It ensures that every part of the system works in harmony, even across large industrial sites.

Why is a DCS Important?

- Centralized Control with Distributed Execution: A DCS allows for centralized monitoring while distributing control functions across multiple controllers, reducing the risk of system-wide failures.

- Scalability: It can easily expand to accommodate growing operational needs.

- Reliability: Redundant systems and fail-safes ensure continuous operation, even in critical environments.

- Efficiency: Optimizes processes, reduces waste, and improves overall productivity.

There are no reviews yet.