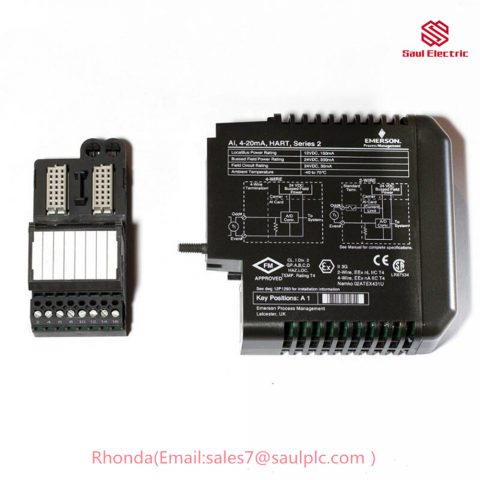

EMERSON SKB3400037

Main Brand:

ABB Allen-Bradley Alstom Bently Emerson Foxboro

GE MOOG Schneider Woodward HIMA Honeywell

First hand source, affordable price. Spot inventory!

•Shipping Port: Xiamen

•Ship to you via Fedex/DHL/TNT/UPS/EMS

•Package: Original packing with cartons

First hand source // Quality assurance // Fast delivery time // Feel free to purchase with confidence

GE DS200TCTGG1A FF GE DS200QTBAG1A GE DS200RTBAG2A HC GE DS200TBQCG1 ABB GE DS200TCRAG1A GE DS200TBCAG1A GE DS200PCCAG4 ADB GE DS200TBQAG1A GE DS200EXPSG1ACB GE 531X307LTBAKGI GE DS200CTBAG1 ADD GE DS200QTBAG1A DC

What is a DCS?

A Distributed Control System (DCS) is a sophisticated, computer-based control system designed to automate, monitor, and manage complex industrial processes. It is widely used in large-scale industrial facilities such as refineries, power plants, chemical plants, and paper mills, where precision, reliability, and scalability are critical.

How Does a DCS Work?

A DCS is composed of several interconnected components that work seamlessly to ensure efficient process control. Here’s a breakdown of its key elements:

- Controllers:

These are the “brains” of the system. Controllers receive data from sensors, process it using pre-programmed logic, and send output signals to actuators to maintain optimal process conditions. - Sensors:

Sensors act as the “eyes and ears” of the system, measuring critical physical parameters such as temperature, pressure, flow rate, and level. This real-time data is essential for accurate control. - Actuators:

Actuators are the “muscles” of the system. They execute physical actions based on controller commands, such as opening/closing valves, starting/stopping motors, or adjusting dampers. - Operator Stations:

These serve as the human-machine interface (HMI), allowing operators to monitor the process, adjust setpoints, and troubleshoot issues. Modern DCS systems often feature intuitive graphical interfaces for ease of use. - Communication Network:

The backbone of the DCS, this network connects all components, enabling seamless data exchange and coordination. It ensures that every part of the system works in harmony, even across large industrial sites.

Why is a DCS Important?

- Centralized Control with Distributed Execution: A DCS allows for centralized monitoring while distributing control functions across multiple controllers, reducing the risk of system-wide failures.

- Scalability: It can easily expand to accommodate growing operational needs.

- Reliability: Redundant systems and fail-safes ensure continuous operation, even in critical environments.

- Efficiency: Optimizes processes, reduces waste, and improves overall productivity.

-480x480.jpg)

-480x480.jpg)

There are no reviews yet.