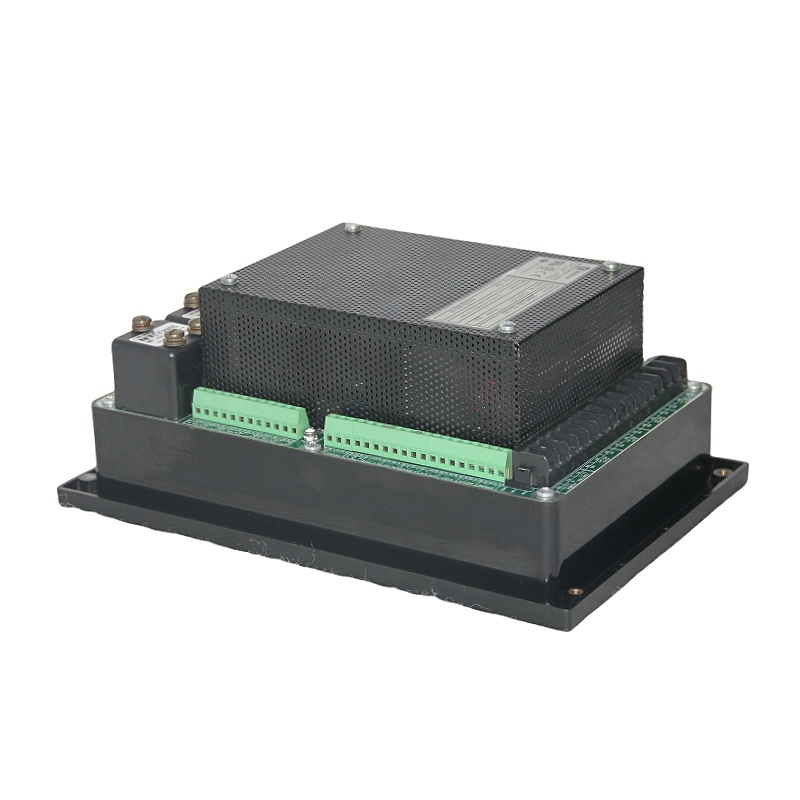

GE 269PLUS-D/O-261-100P-120

The GE 269PLUS-D/O-261-100P-120 is a motor management relay from GE Multilin’s 269 Plus series. It’s designed to provide comprehensive protection and control for medium-sized three-phase AC motors. Here’s a summary of its key technical parameters:

⚙️ 1. Basic Specifications

- Model: 269PLUS-D/O-261-100P-120

- Brand: GE (General Electric)

- Manufacturer: GE Multilin

- Rated Voltage: 120V AC

- Input Voltage: 125V DC (for the control circuit)

- RTD (Resistance Temperature Detector): 100 Ohm platinum RTD for accurate temperature monitoring

- Weight: Approximately 7.75 lbs (3.52 kg)

- Shipping Dimensions: 11.40″ x 7.50″ x 16.00″ (W x H x D)

🛡️ 2. Protection Functions

The relay offers extensive motor protection features:

- Thermal Overload Protection: Includes 8 standard overload curves and a user-definable FlexCurve™ for customized protection

- Short Circuit Protection: Guards against high-current faults

- Ground Fault Protection: Detects ground leakage currents

- Unbalance/Single Phasing: Protects against phase unbalance and loss of a phase

- Locked Rotor: Detects and protects against motor stalling

- Undercurrent (Loss of Load): Monitors for a drop in motor current indicative of load loss

- Phase Reversal: Detects incorrect phase sequence

- RTD-Based Temperature Monitoring: Provides protection for stator windings and bearings against overheating using up to 12 programmable RTD inputs

- Jam/Quick Trip: Protects against mechanical jamming

- Start Inhibition: Manages multiple motor starts

- Under/Over Voltage: Available with the metering option

📊 3. Control and Monitoring Features

- Thermal Model Bias: Enhanced model includes current unbalance and RTD bias for accurate thermal protection

- Pre-Trip Alarm: Provides early warning before a trip occurs

- Emergency Restart: Allows for emergency override under certain conditions

- Lockable Trip Relay: Main trip relay with latching function

- Variable Lockout Time: Adjustable lockout time after a trip

🔌 4. Inputs and Outputs

- Digital Inputs: 5 factory-programmed digital inputs

- Output Relays: 4 output relay contacts (including main trip, alarm, and two auxiliary relays)

- Analog Output: 1 programmable analog output (e.g., for motor thermal capacity, current, or RTD temperature)

- RTD Inputs: 12 programmable RTD inputs for temperature sensing

📶 5. Communication and Metering

- Communication Protocol: Supports Modbus RTU via a standard RS-485 serial port for integration into control systems

- Metering Functions: Provides monitoring of:

- Average and individual phase currents

- Motor load (% of full load)

- RTD temperatures (hottest, individual, max)

- Unbalance ratio (% In/Ip)

- Ground leakage current

- Thermal capacity used and time to trip

- Optional voltage, power, power factor, frequency, and energy metering (with metering option)

- Data Logging: Includes a data logger for recording trends and events

- Learning and Statistics: Captures motor running and learning data, including last trip information for diagnostics

🖥️ 6. Programming and Interface

- Display: Simple LED display for real-time information

- Keypad: 12-key keyboard for programming and configuration

- Software: Configured using GE’s EnerVista software for setup, monitoring, and integration into existing control systems

- Field Upgradable: Settings and firmware can be upgraded in the field

🌡️ 7. Environmental Conditions

- Operating Temperature: -25°C to +60°C

- Storage Temperature: -25°C to +60°C

- Relative Humidity: Up to 95% non-condensing

🏭 8. Physical and Installation

- Enclosure: Designed for industrial environments.

- Installation: Must comply with all national and local electrical codes

🚀 9. Applications

This relay is suitable for various industrial applications involving medium-voltage motors, including:

- Pumps, fans, compressors

- Conveyors

- Renewable energy systems (e.g., wind, solar)

- Transportation systems (e.g., electric vehicles, rail)

- Industrial machinery in manufacturing, energy, and infrastructure sectors

There are no reviews yet.