GE DS200TCEBG1ACE Technical Specifications

Comprehensive technical details and specifications for the General Electric DS200TCEBG1ACE terminal board used in Mark-V control systems.

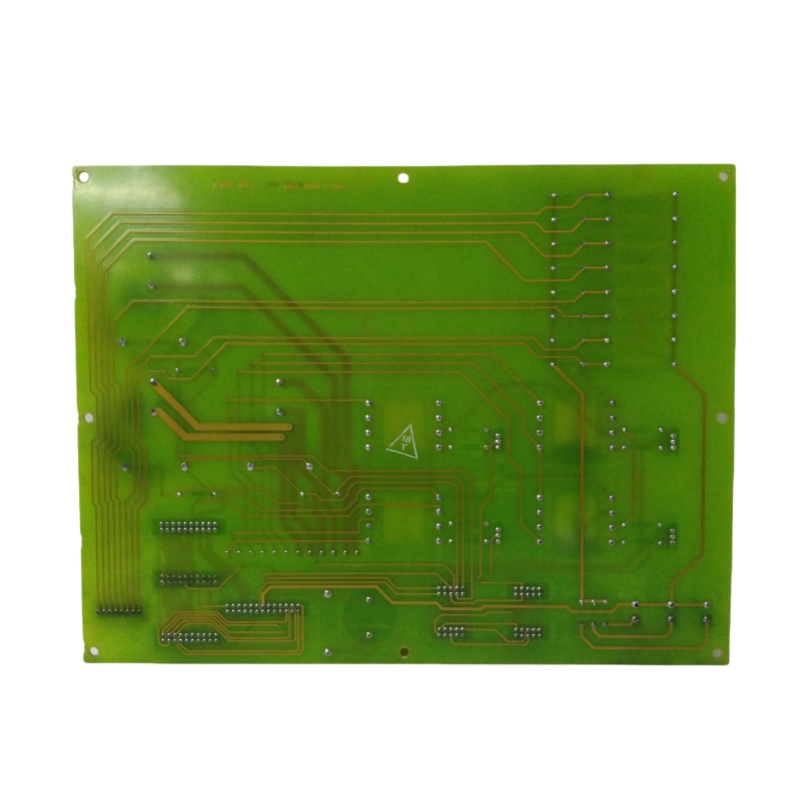

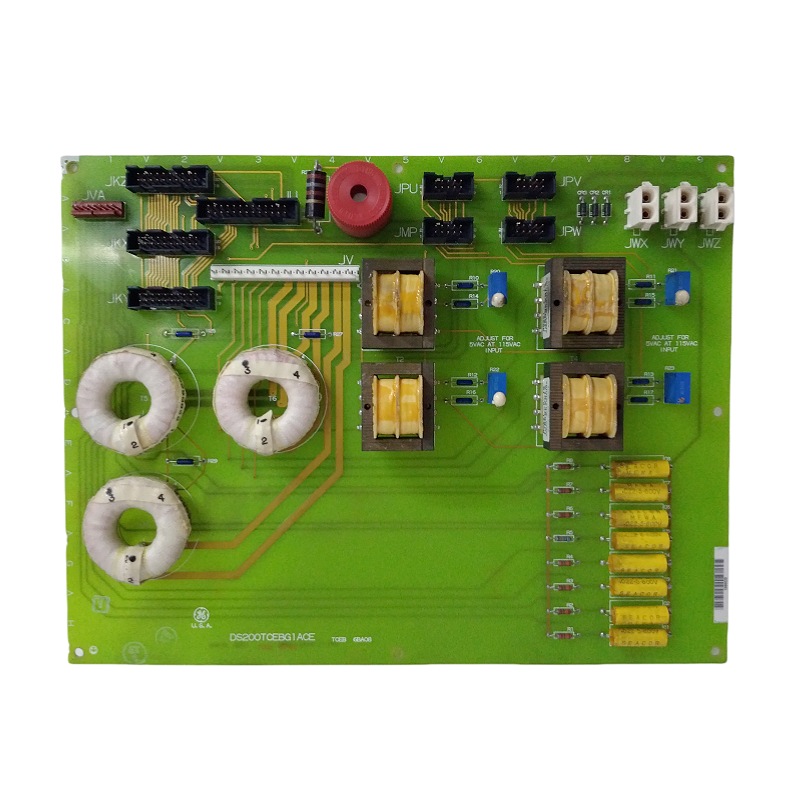

DS200TCEBG1ACE Technical Overview

The GE DS200TCEBG1ACE is a terminal board designed for use in General Electric’s Mark-V turbine control system. This component plays a critical role in providing connection points for various signals and power distribution within the control system architecture.

Technical Specifications

| Parameter | Specification |

|---|---|

| Part Number | DS200TCEBG1ACE |

| Manufacturer | General Electric (GE) |

| Product Type | Terminal Board |

| Compatible System | Mark-V Turbine Control System |

| Number of Terminals | 48 |

| Terminal Type | Screw-type connections |

| Voltage Rating | 300V |

| Current Rating | 10A per terminal |

| Board Material | Fire-resistant epoxy glass |

| Operating Temperature | -20°C to 85°C (-4°F to 185°F) |

| Storage Temperature | -40°C to 100°C (-40°F to 212°F) |

| Dimensions | Approx. 6.5″ x 4.2″ x 1.5″ (165mm x 107mm x 38mm) |

| Weight | 0.45 lbs (0.2 kg) |

| Certifications | UL94V-0, CE compliant |

Key Features

- High-density terminal configuration for space-efficient installation

- Robust construction for industrial environments

- Clear terminal numbering for easy identification and wiring

- Compatible with standard wiring practices

- Designed for reliable performance in critical control applications

- High-quality materials ensure long-term reliability

Typical Applications

The DS200TCEBG1ACE terminal board is specifically designed for use in:

- GE Mark-V gas turbine control systems

- Power generation facilities

- Industrial turbine control applications

- Power distribution systems

- Signal termination and distribution

Installation Notes

When installing the DS200TCEBG1ACE terminal board, ensure proper mounting using the provided fixtures. Follow all applicable electrical codes and safety procedures. Use appropriate torque when tightening terminal screws to ensure secure connections without damaging the terminals.

Maintenance

Regular inspection of the terminal board is recommended as part of preventative maintenance routines. Check for signs of overheating, loose connections, or corrosion. Ensure the board remains free of dust and contaminants that could affect performance.

There are no reviews yet.